Stationary Laser Screed Product Line

In 1986, Somero Enterprises was founded and so marked the first industry-wide revolution that the company would embark upon. Dave and Paul Somero were concrete contractors, and they knew that a machine could get them better quality floors with more efficiency all with a faster process than the current manual methods of placing concrete. Not wanting to wait on a company to manufacture the machines that would deliver this Faster.Flatter.Fewer solution, they took it upon themselves and 35 years later the idea of doing a big, quality-driven slab-on-grad projects without a Somero® Laser Screed® Machine is almost un-thinkable.

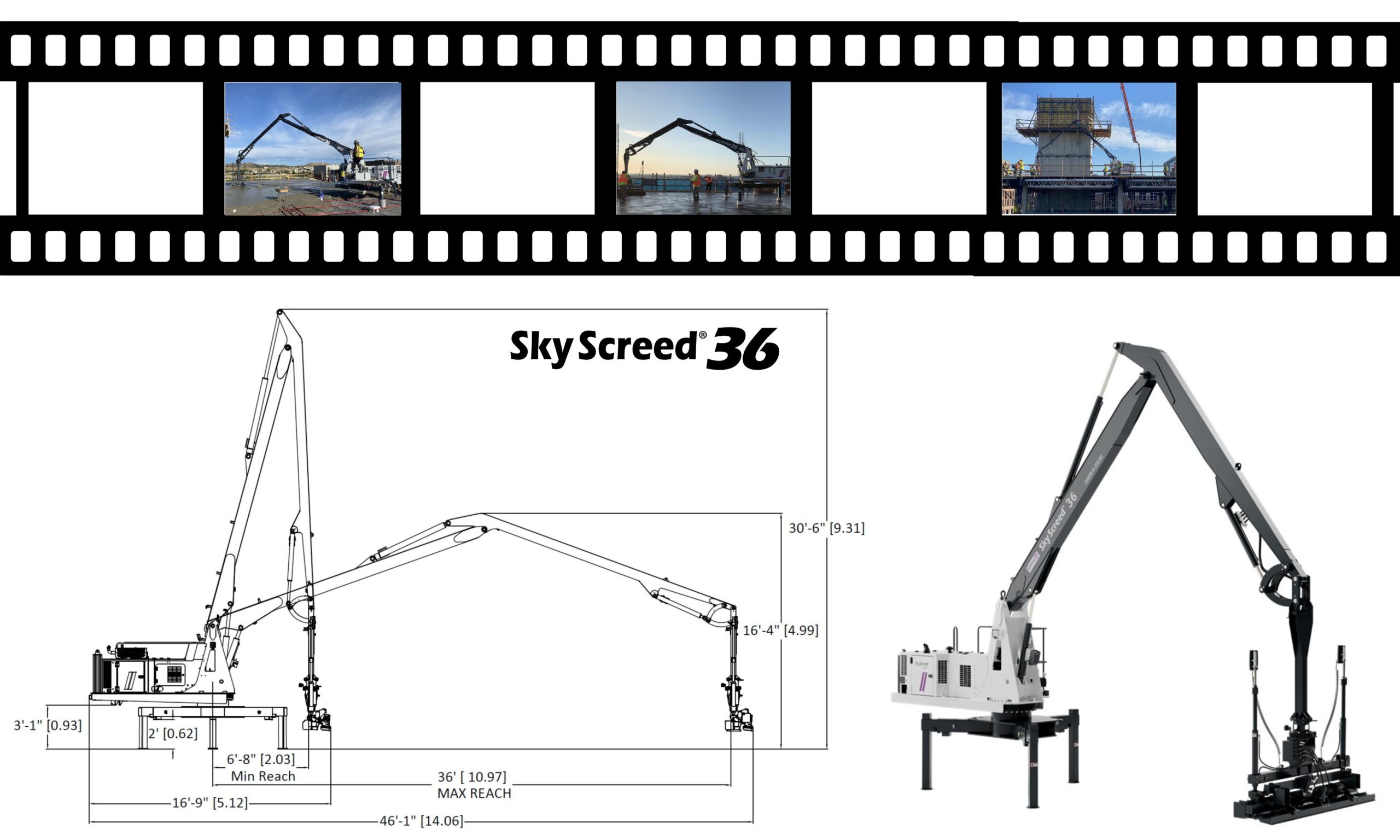

With this same industry-changing mindset and self-reliance that created the first laser screed machine in 1986, we are embarking on our second revolutionary machine innovation – The SkyLine machine line. Consisting of the SkyScreed® 36 Laser Screed® Machines, we are looking to partner with the structural high market and deliver quality, safety and efficiencies never thought possible for concrete floors in this space.

The SkyScreed® brings the precision and speed of the laser screed® machine to structural projects and we promise you won’t believe the numbers when you hear them. With the right project profile and layouts, the SkyScreed® 36 has achieved Fl numbers in the mid-to-high 30s and in some case the low-to-mid 40s. The early adopters of this technology have been blow away and we believe that is it just a matter of the SkyScreed will be the rule on high rise projects all over North America.

Features and Benefits

SkyScreed 36

- 36′ (10.97 m) OR 25′ / 7.6m Knuckle Boom

- OASIS Laser Control System

- 8′ / 2.6m Floating Vibrator Screed Head

- Somero Quick GradeSet System™

- 360° Machine Base/Screed Head Rotation

- Patented Self Leveling System – SLS

- Set Up Jig

- Wireless Remote Control

- Auxiliary Power Unit

- Programmable Quick Pass

- Column-Block Protection

- Automatic Hydraulic Oil warming

- On-board Pressure Washer

- Storage

- Lift Harness & Tag Line

- Positioning Buckets

Base Specifications

See the machine brochures for specific machine details.

What Our Customers Are Saying

“Working with the SkyScreed we were able to save 90 minutes on our deck with 5 fewer men.”

Randy Bergakker

Kent Companies

Somero SkyScreed Laser Screed Machine

We’re proud to introduce the Somero Sky Screed Laser Screed Machine, the first Knuckle Boom Laser Screed machine in the world to allow screeding on structural high-rise and slab-on-grade applications. This revolutionary Laser Screed machine was developed to increase labor savings, improve floor quality, and increase productivity. The innovative articulating knuckle boom makes all of this possible by providing unparalleled versatility.